Innovative medical solution for bone regeneration

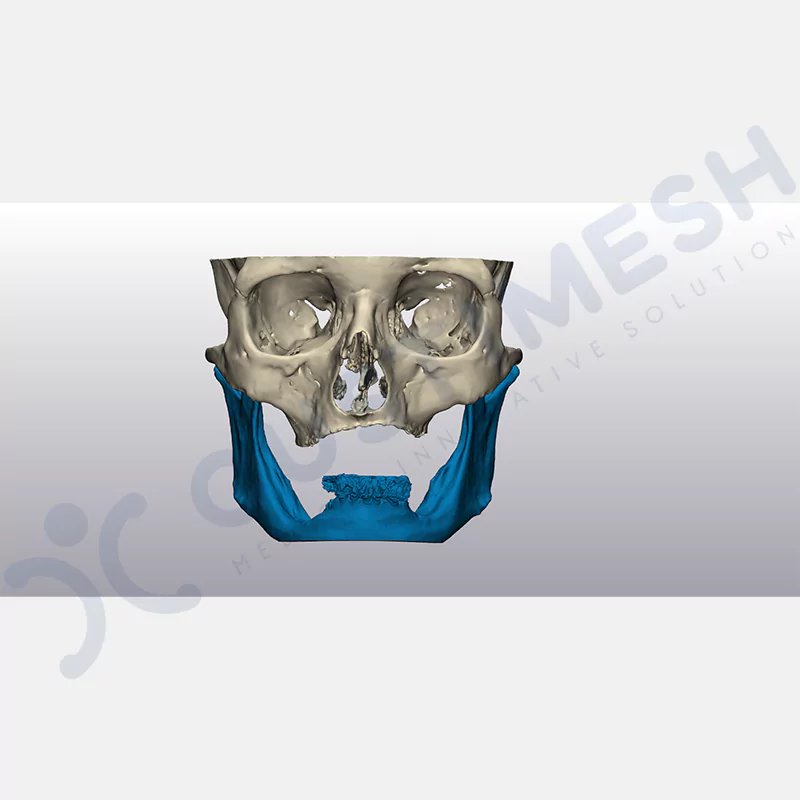

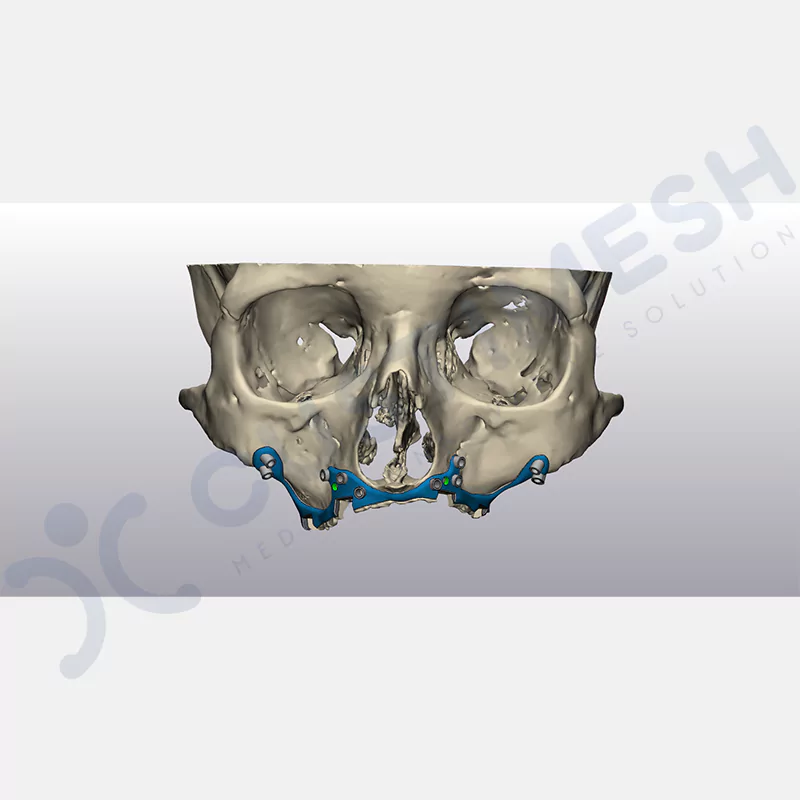

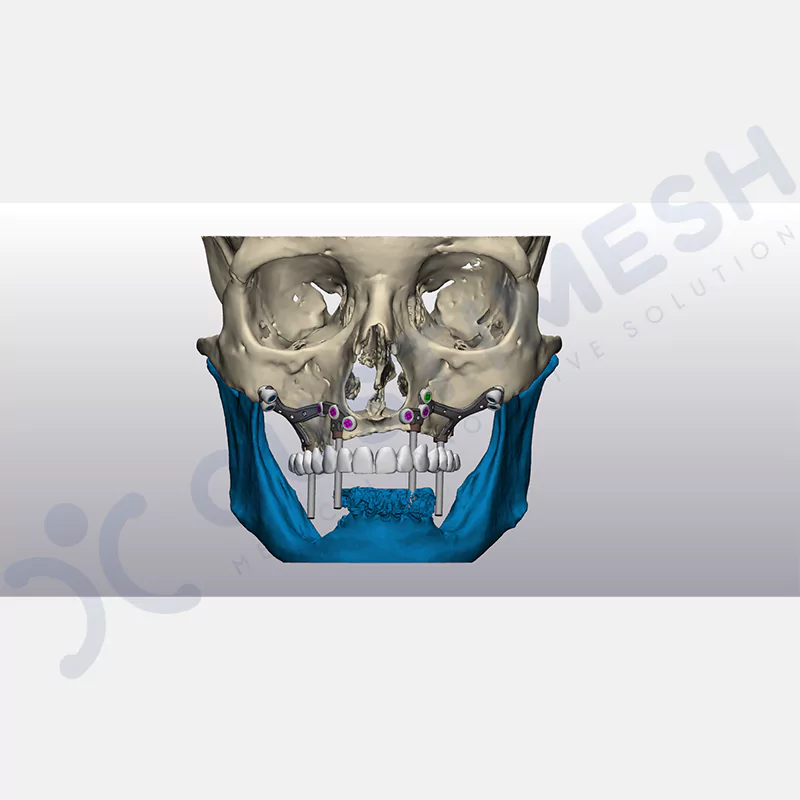

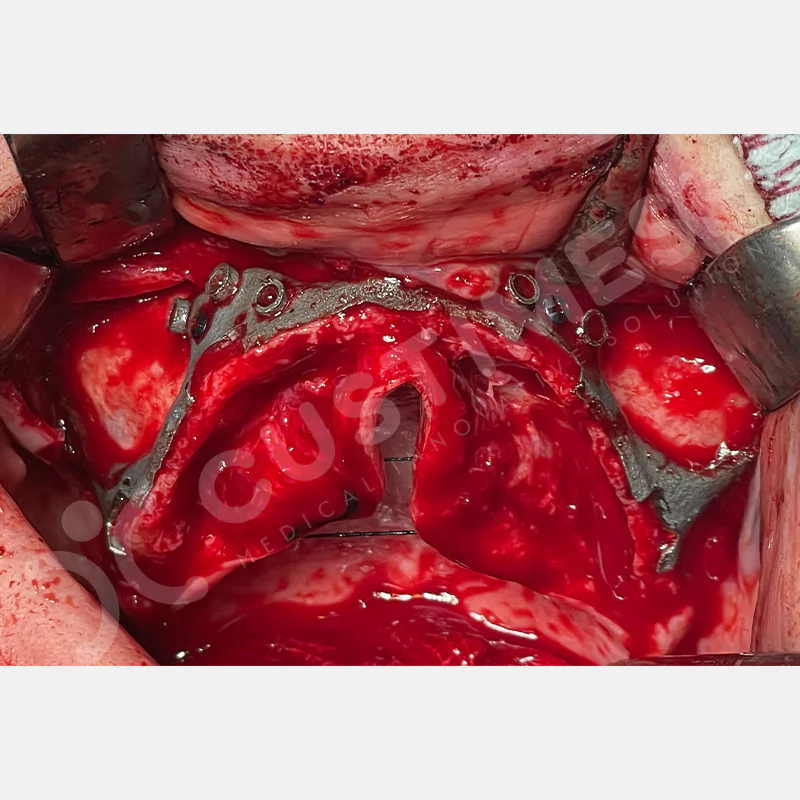

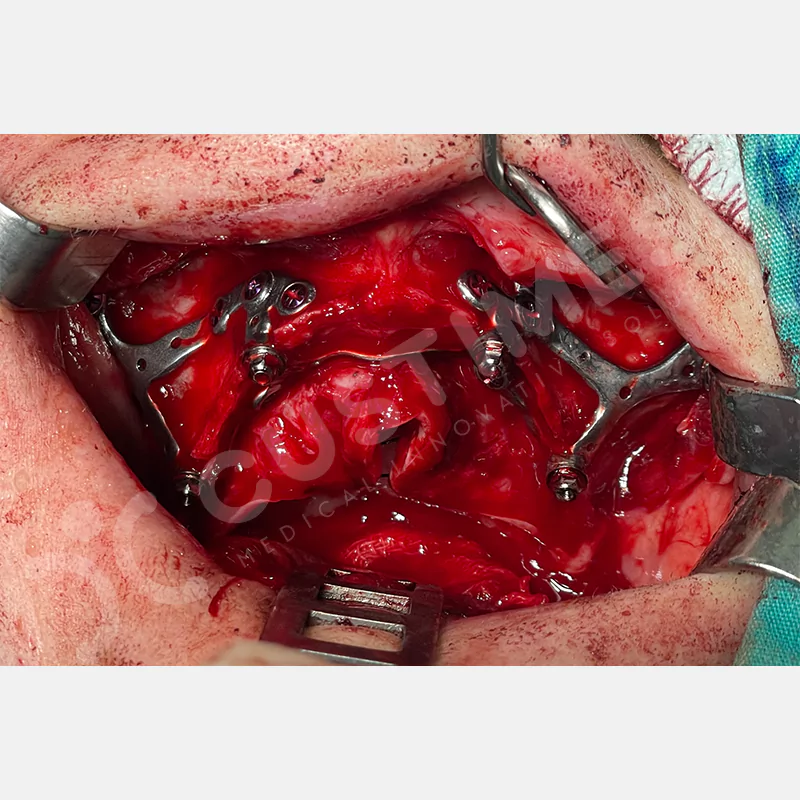

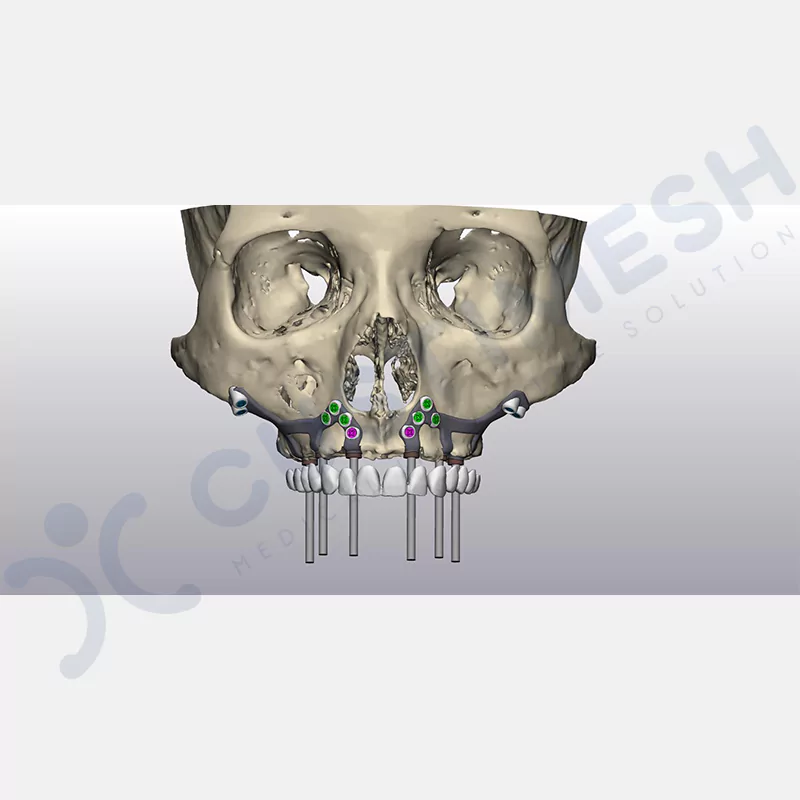

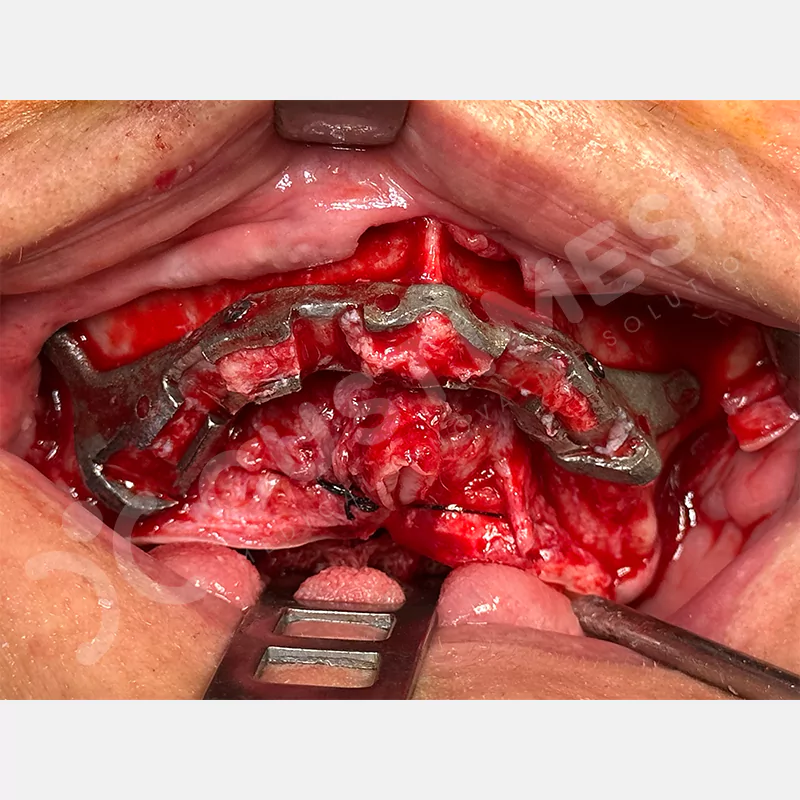

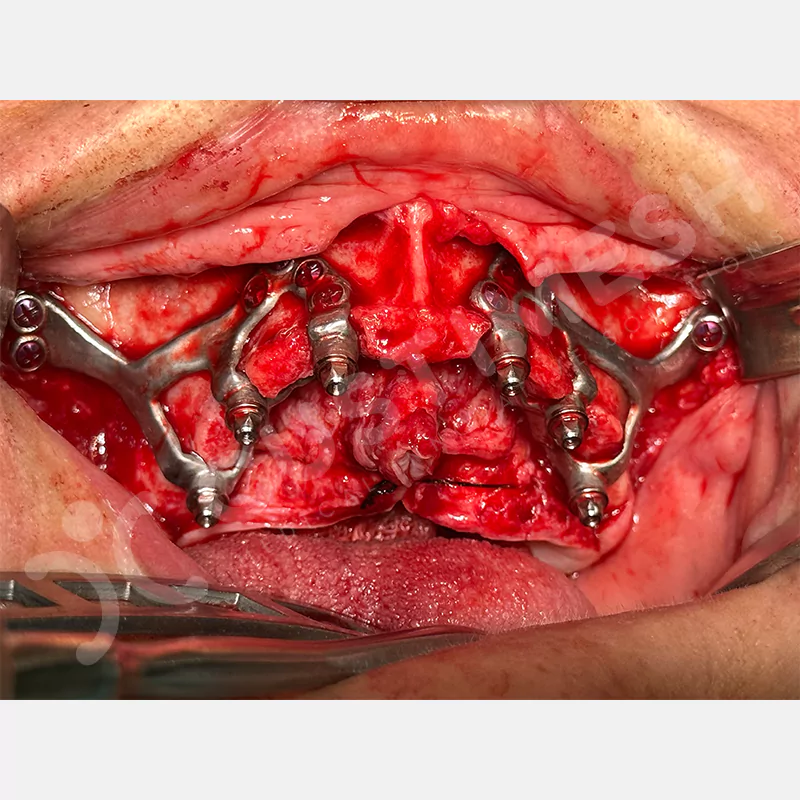

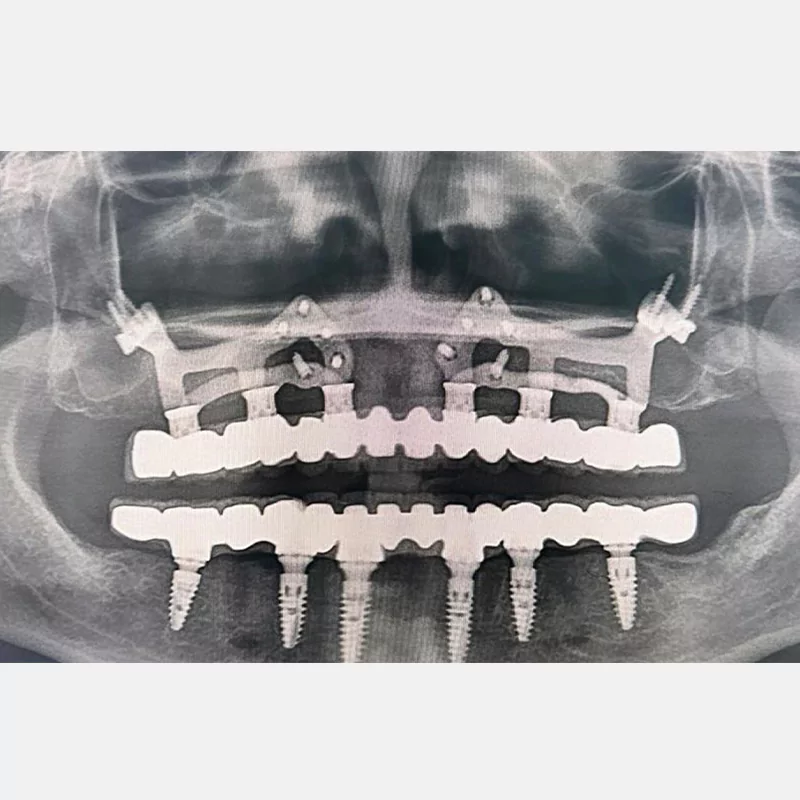

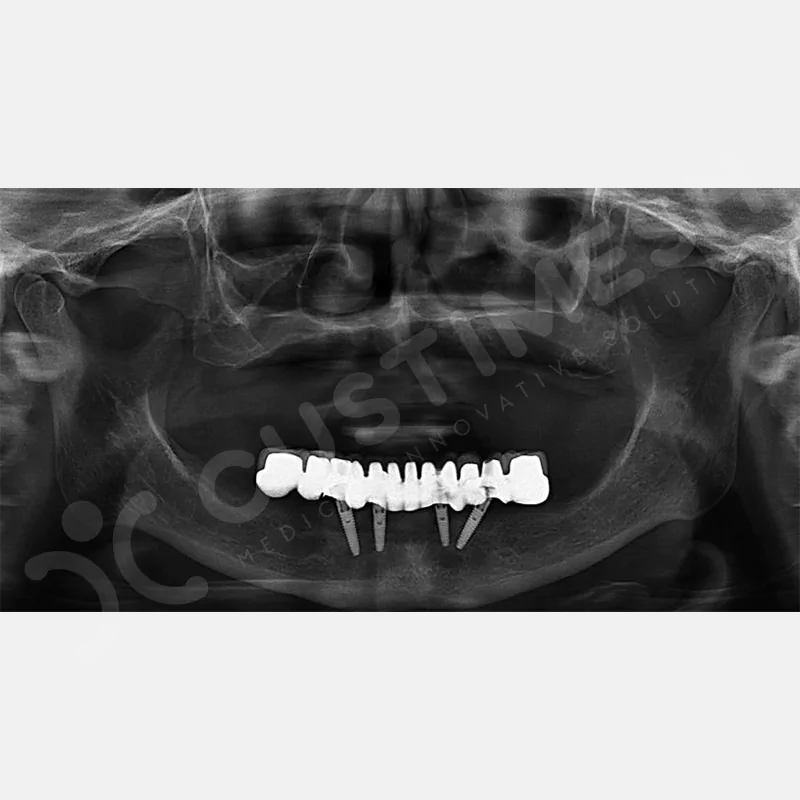

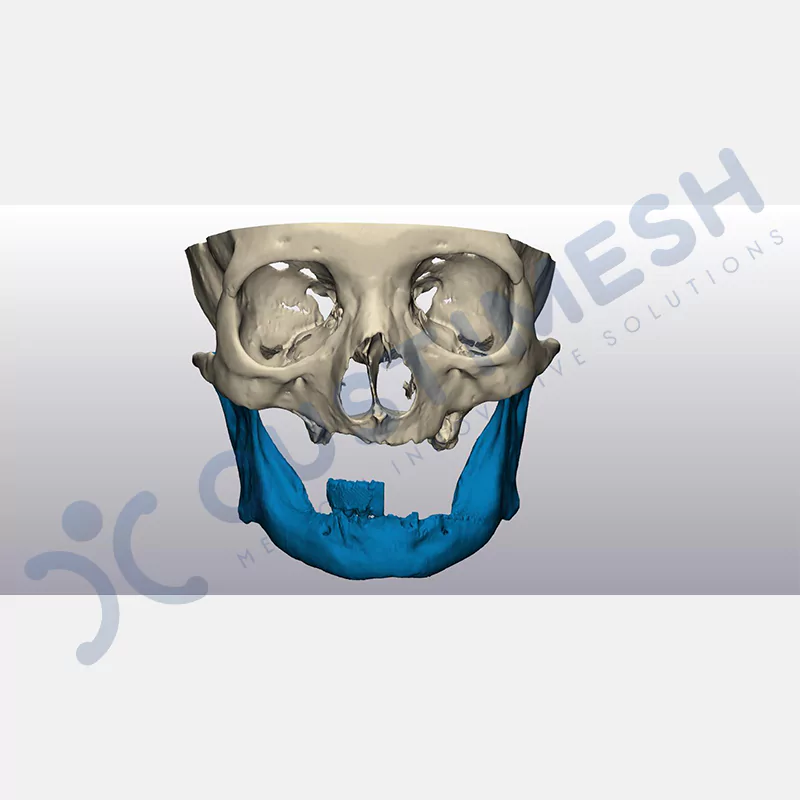

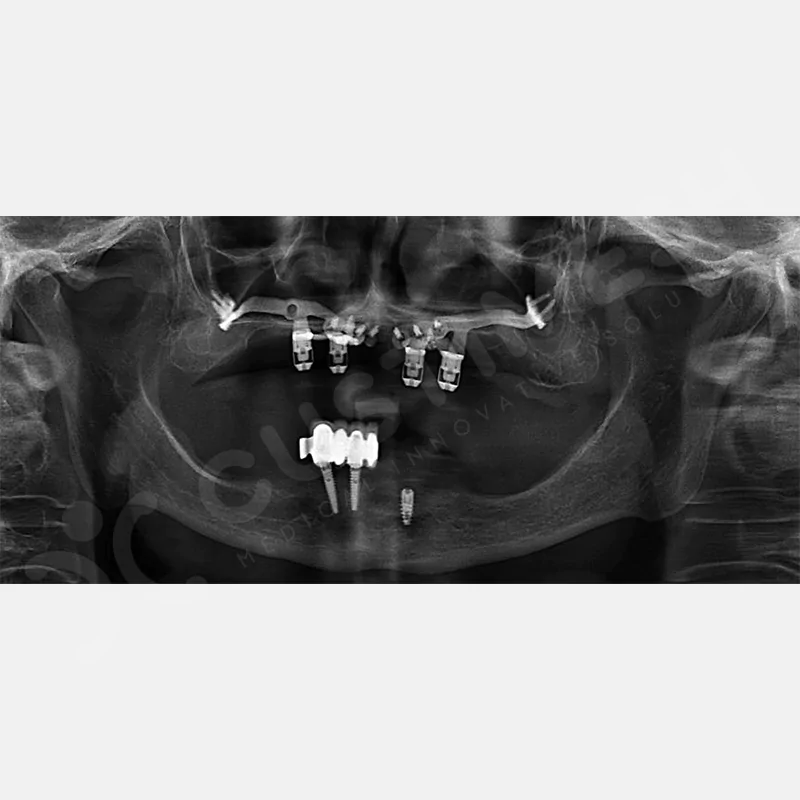

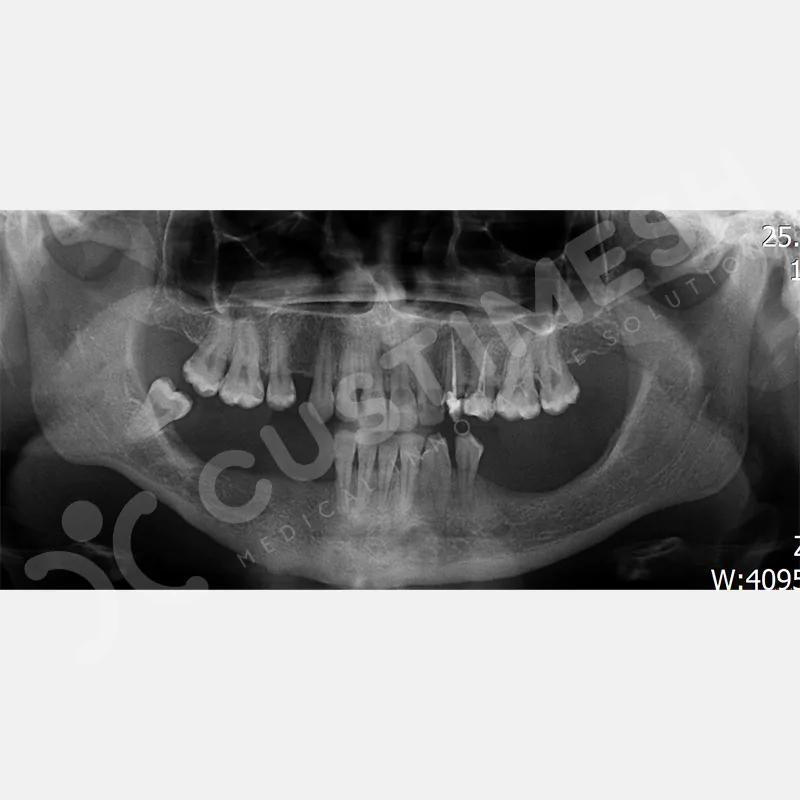

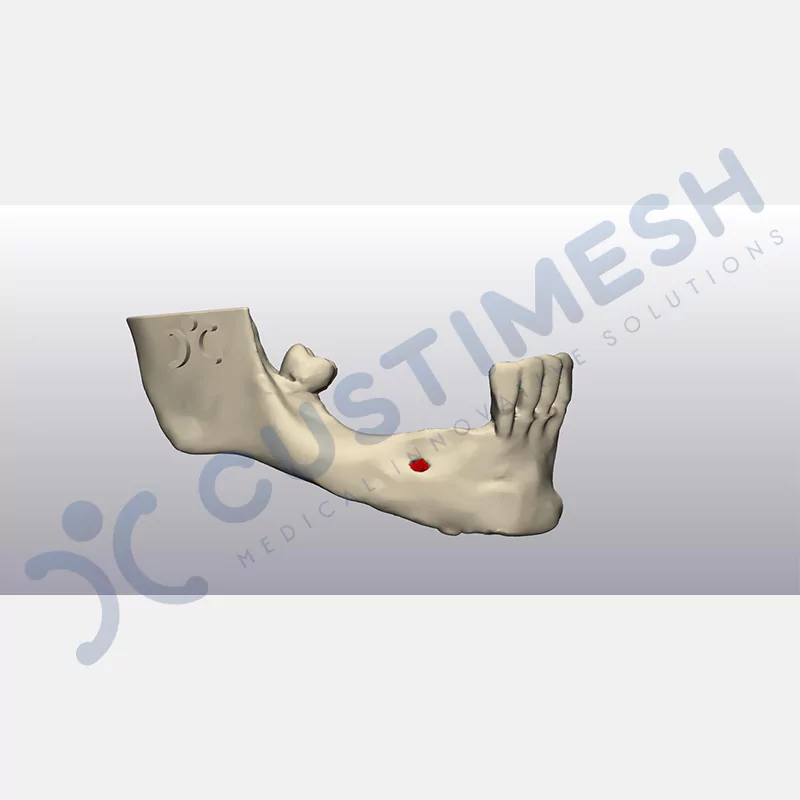

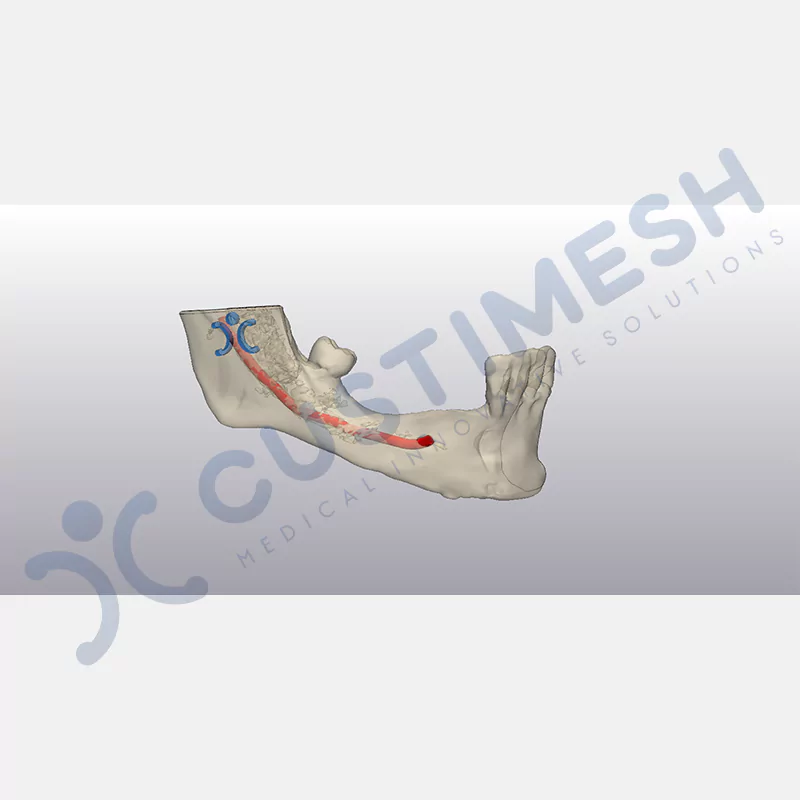

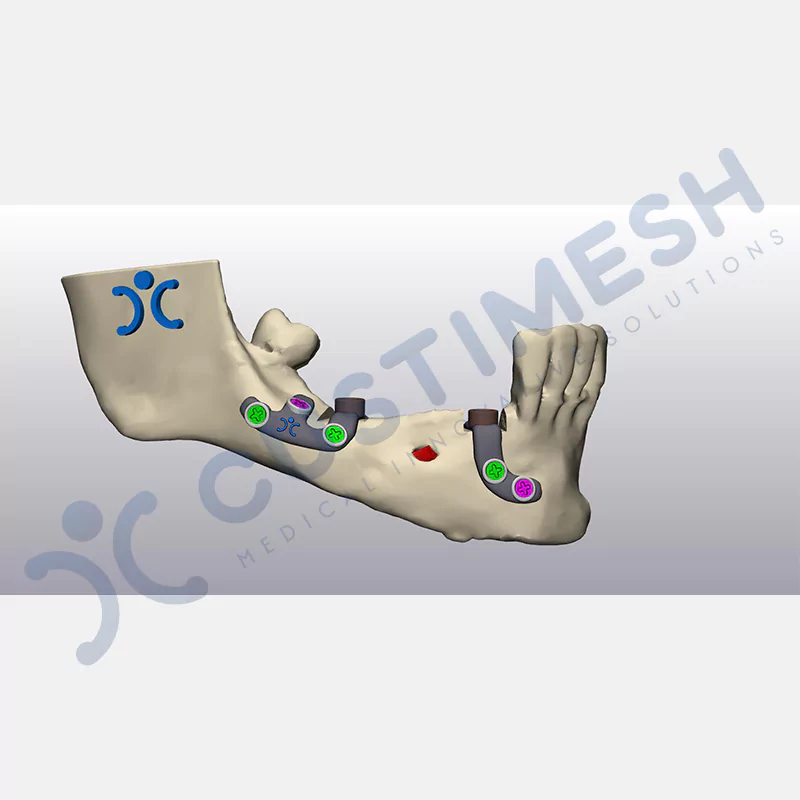

The Personalized Subperiosteal Implant is a personalized implant designed with CAD/CAM technology for people who have not completed their jaw development and do not have sufficient bone support. This implant, developed using computer-aided design software with data obtained from computerized tomography images, is produced with the laser sintering method.

Customized Subperiosteal Implant (CUSTIMPLANT)

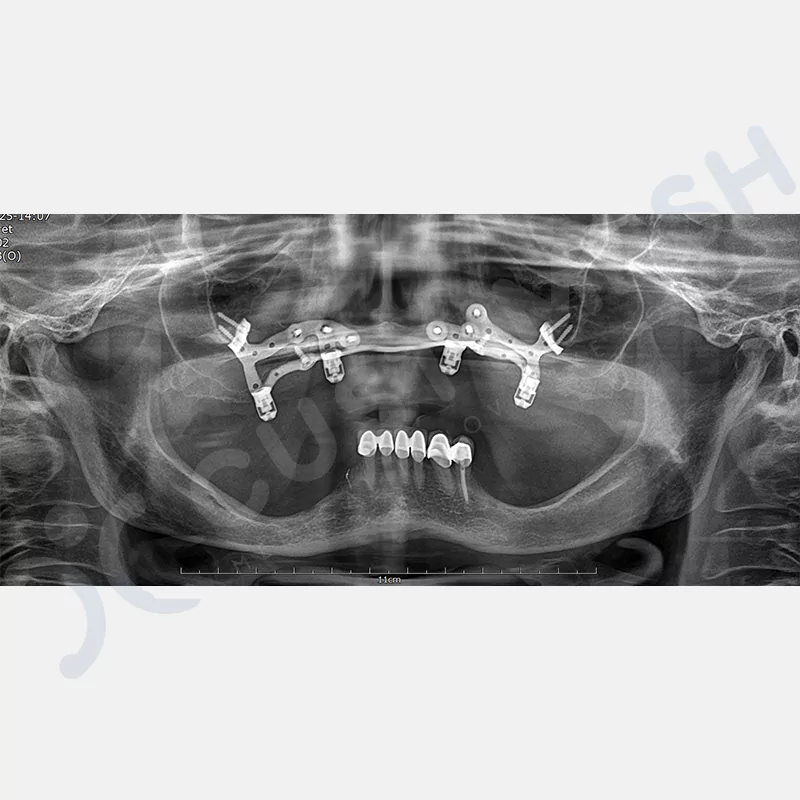

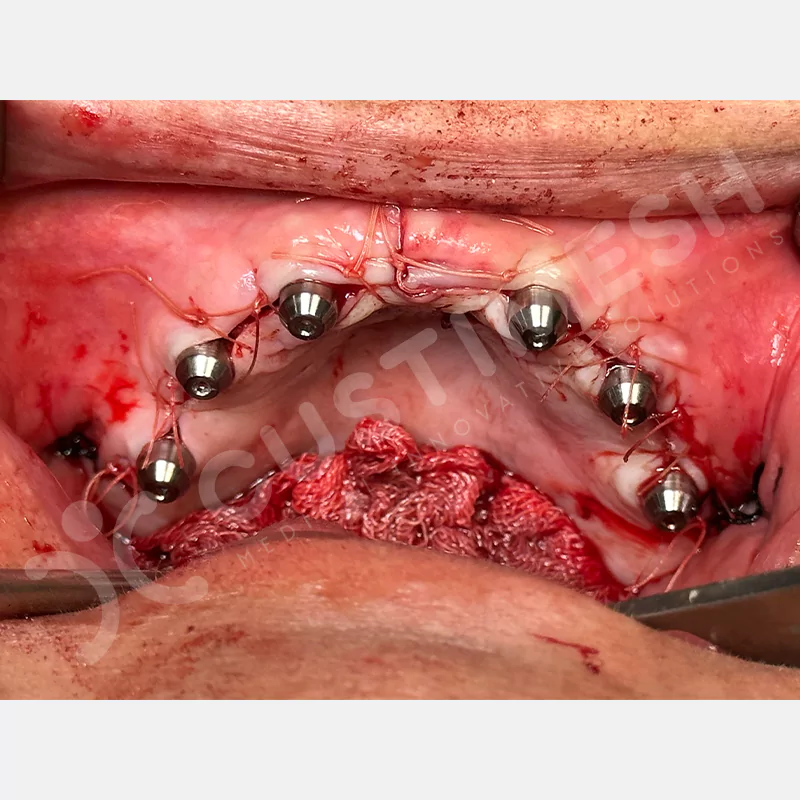

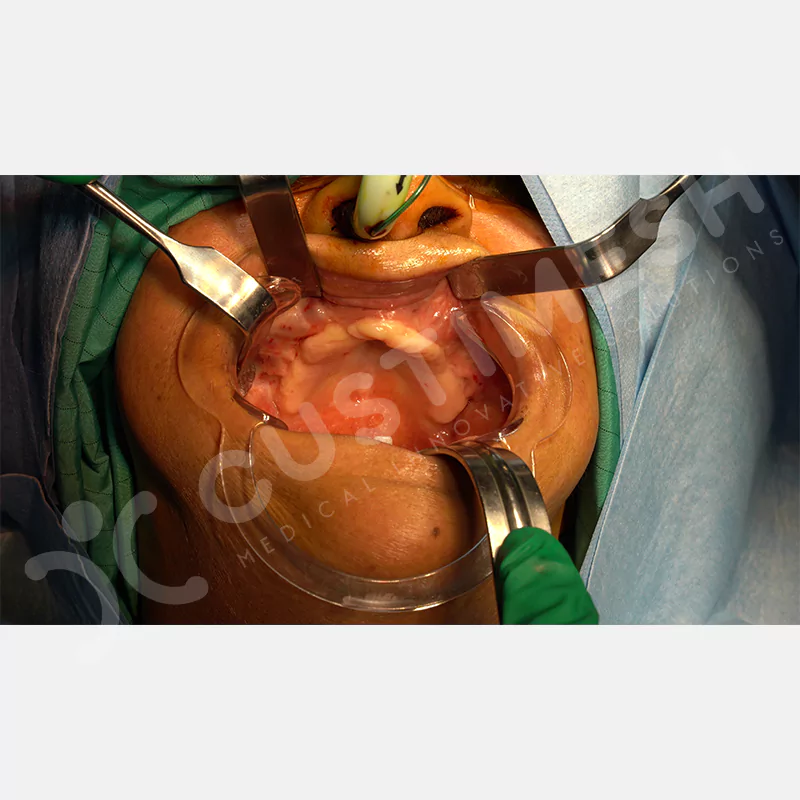

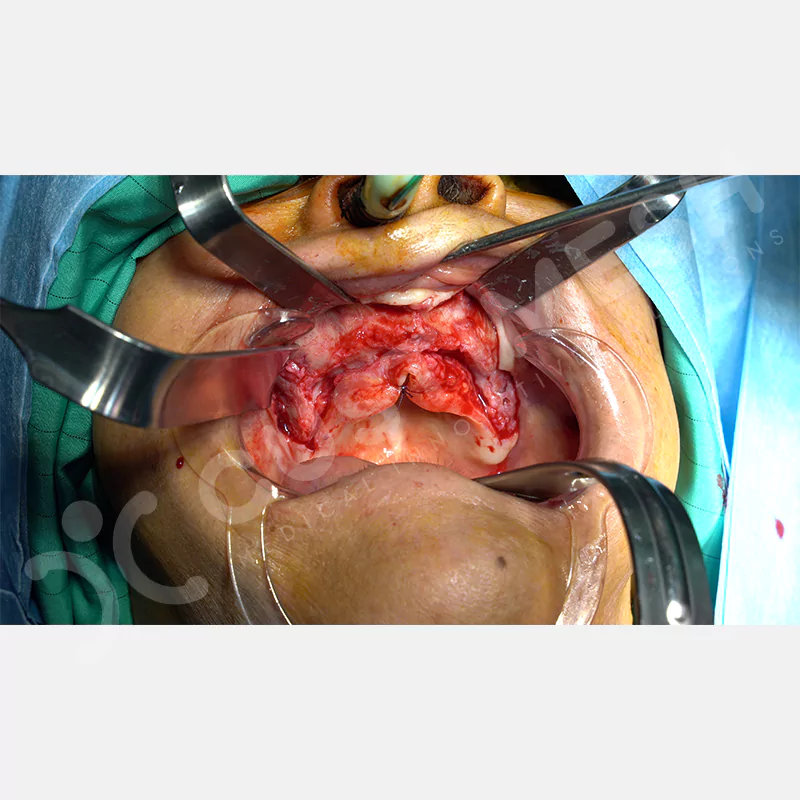

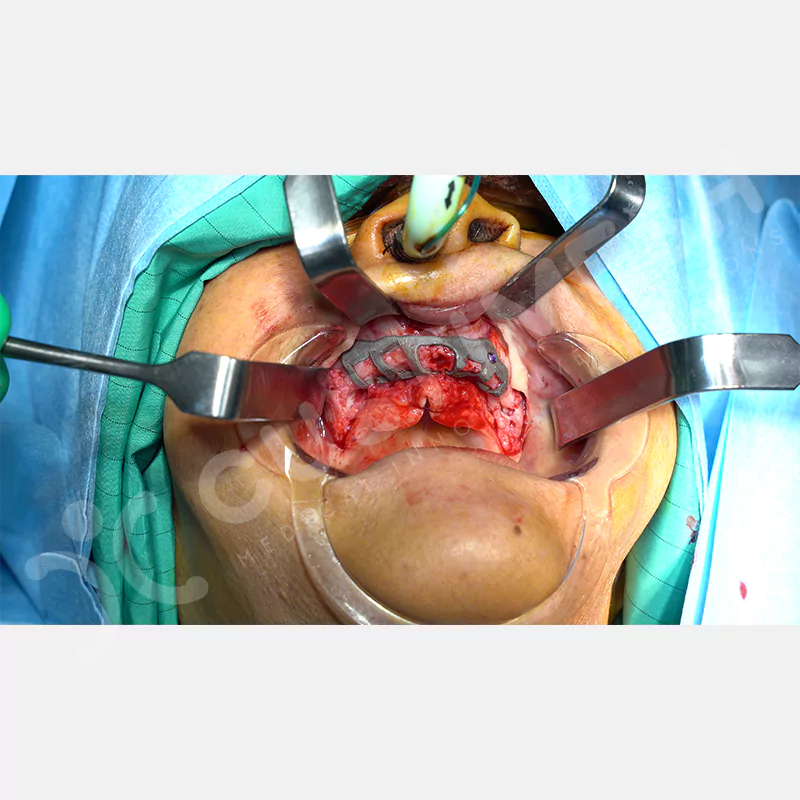

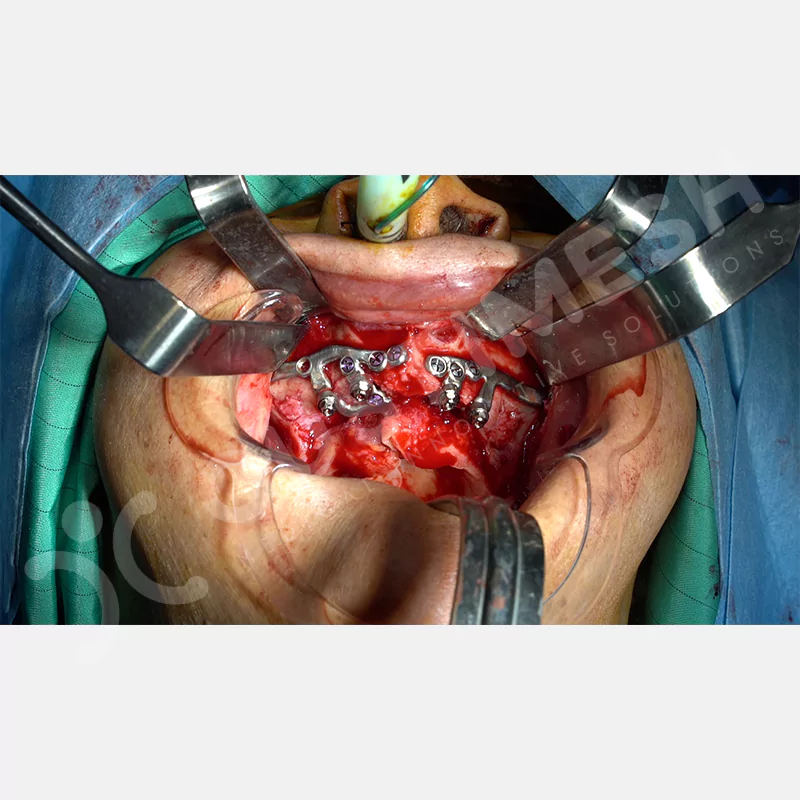

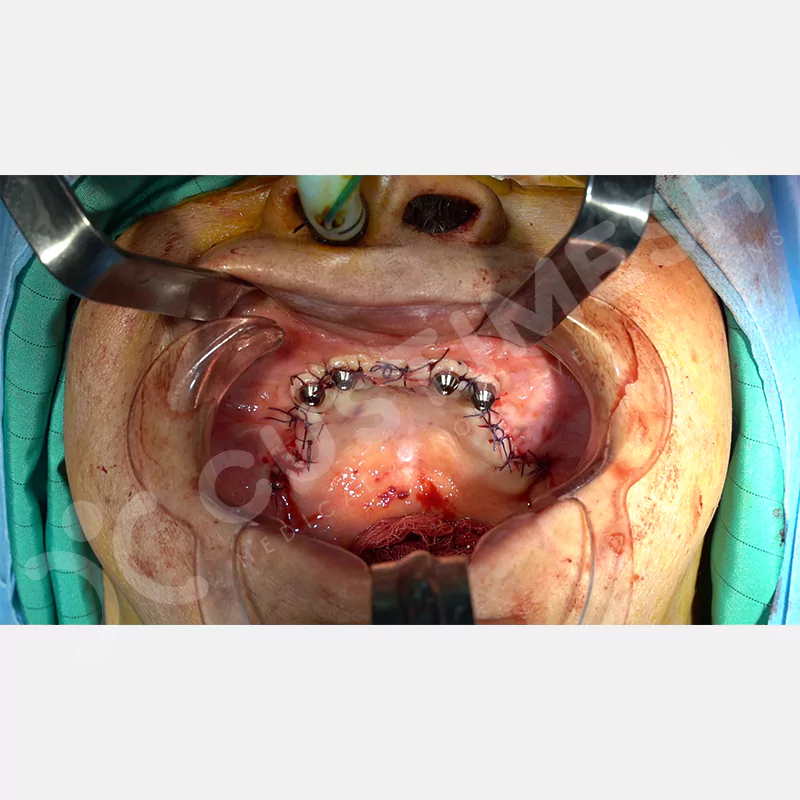

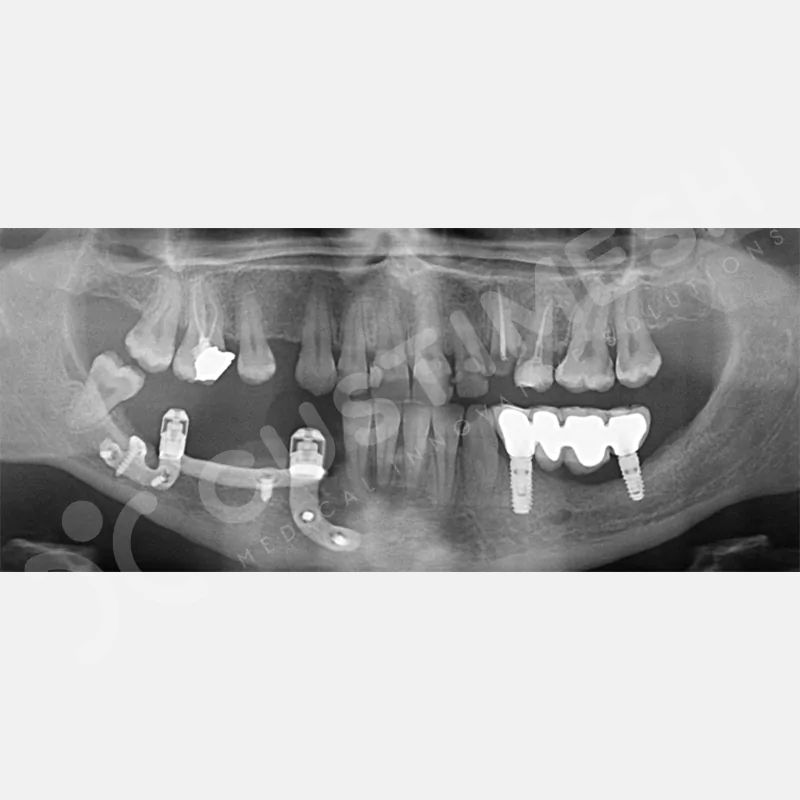

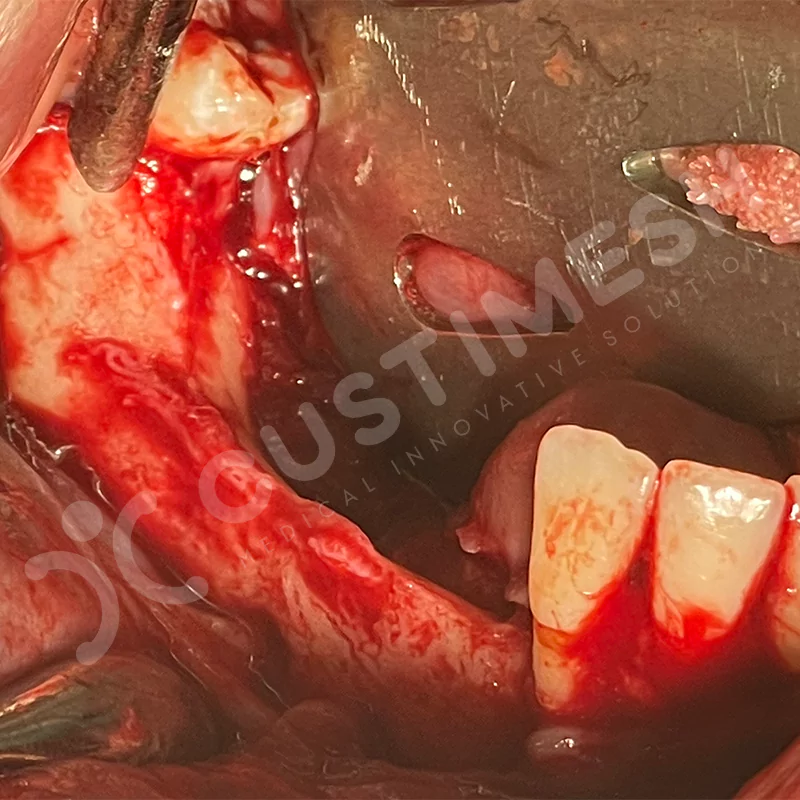

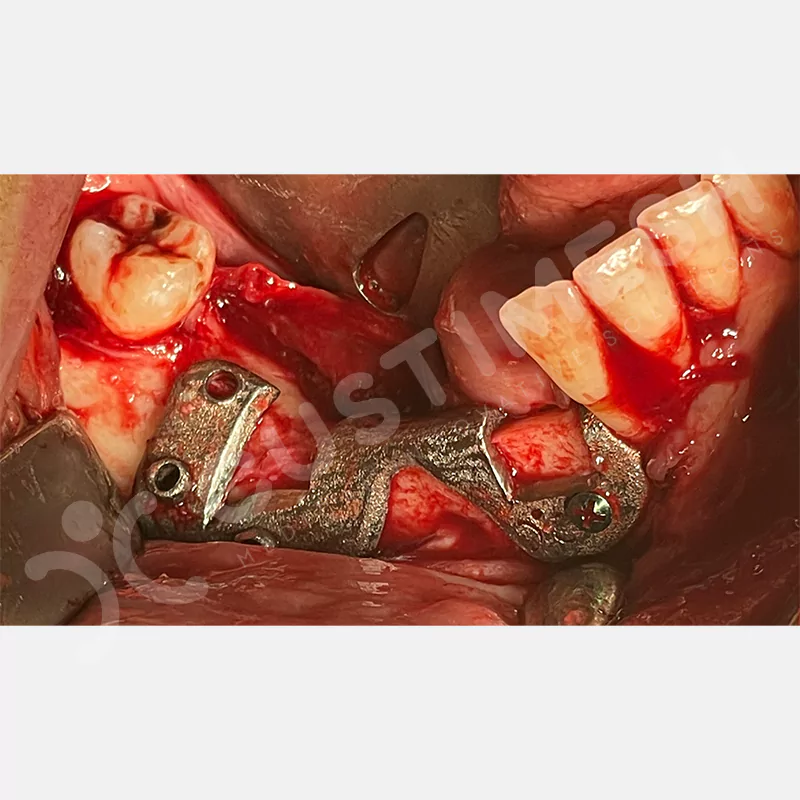

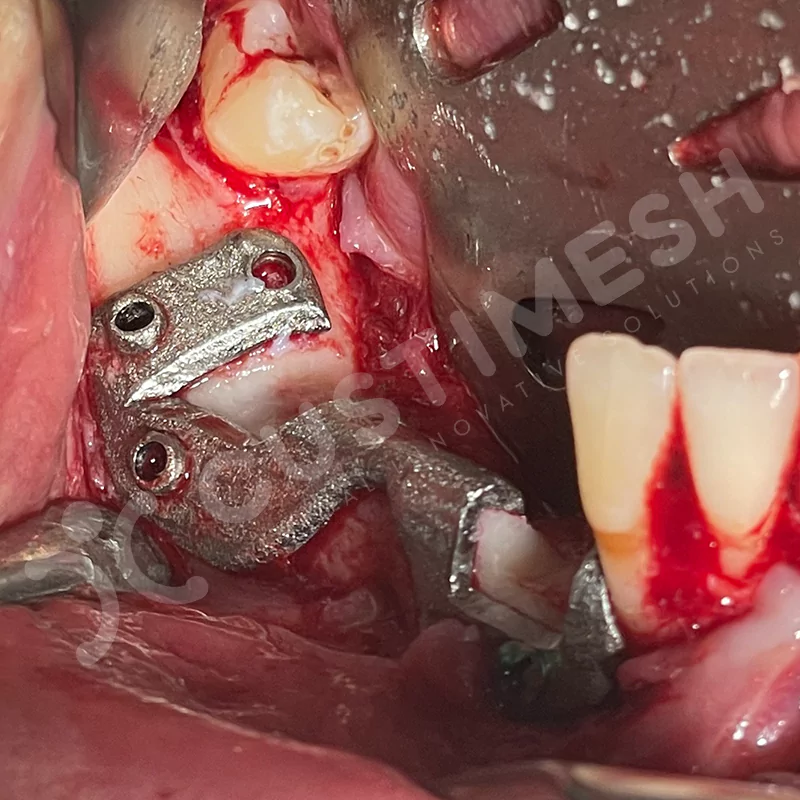

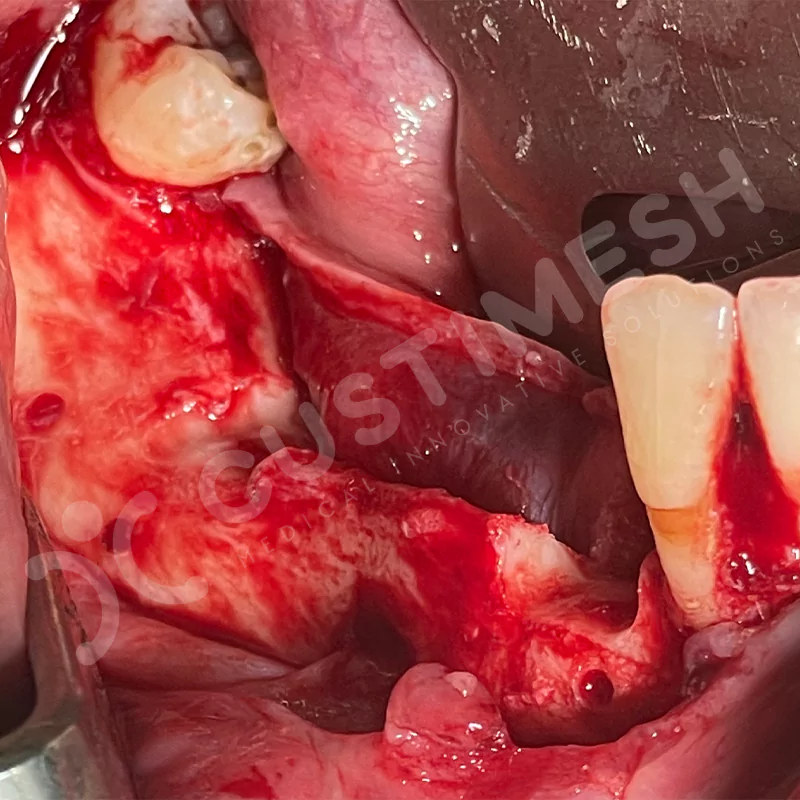

In modern dentistry, customized titanium implants offer solutions for patients with incomplete jaw development or severe bone loss. These implants, produced using CAD/CAM technology and laser sintering, perfectly adapt to the patient’s individual anatomical structure, providing an excellent alternative in cases where traditional implants cannot be applied.Subperiosteal implants, specifically developed for patients with advanced bone loss, are placed beneath the periosteum, offering a minimally invasive approach. Thanks to designs optimized with CT data and finite element analyses, they guarantee both aesthetic and functional outcomes.

This innovative technology allows for implant and prosthesis application in a single session, enabling patients to achieve their natural smile on the same day. It also eliminates the need for additional procedures like bone grafting, significantly simplifying the surgical process.With their custom design and superior biocompatibility, these implants deliver successful results even in complex cases previously considered untreatable. They open a new era in modern dentistry, aiming to improve patients’ quality of life.

- Custom Design

- Perfect Fit

- Grade 23 Medical-Grade Titanium Material

- RBM Inner Surface

- Polished Outer Surface

- Reinforced Multiunit

- Multiunit Suitable for Different Gum Levels

- Alignment with Reduction Guide when Necessary

- 2 mm Diameter Titanium Screw for Fixation

- Screw Holes Designed According to Anatomical Boundaries

- Pink Anodization Compatible with Gum Color

CUSTIMPLANT | Order and Delivery Process

- DICOM The patient’s DICOM file should be sent via WeTransfer to custimesh.case@gmail.com. *The doctor’s name and the relevant area for the Custimesh procedure should be specified in the *DESCRIPTION section. For Custimesh, a CBCT scan with a slice thickness of 0.2 – 0.5 mm should be performed, covering the treatment area with the appropriate field of view (FOV). (FOV).

- DOCTOR A 3D model is prepared based on the area where the mesh will be planned, presented to the doctor for approval, and communication is established with the doctor for necessary evaluation.

- PAYMENT At this stage, payment is made, and active design begins, transitioning to the surface design process.

- DESIGN The surface design for the relevant area is created, taking anatomical contours into consideration. It is then submitted for the doctor’s approval. Once approved by the doctor, the surface design is transformed into the mesh form, with consideration given to safe screw regions and appropriate condensation points.

- DOCTOR APPROVAL The final design of the customized Custimesh, prepared for production, is presented to the doctor for approval.

- PRODUCTION The Custimesh, approved by the doctor, is produced using 3D printing technology from Grade 23 (Ti6Al4V) Medical Titanium Alloy.

- SHIPPING The Custimesh, after undergoing the necessary postprocessing stages, is carefully prepared and shipped to the relevant doctor.

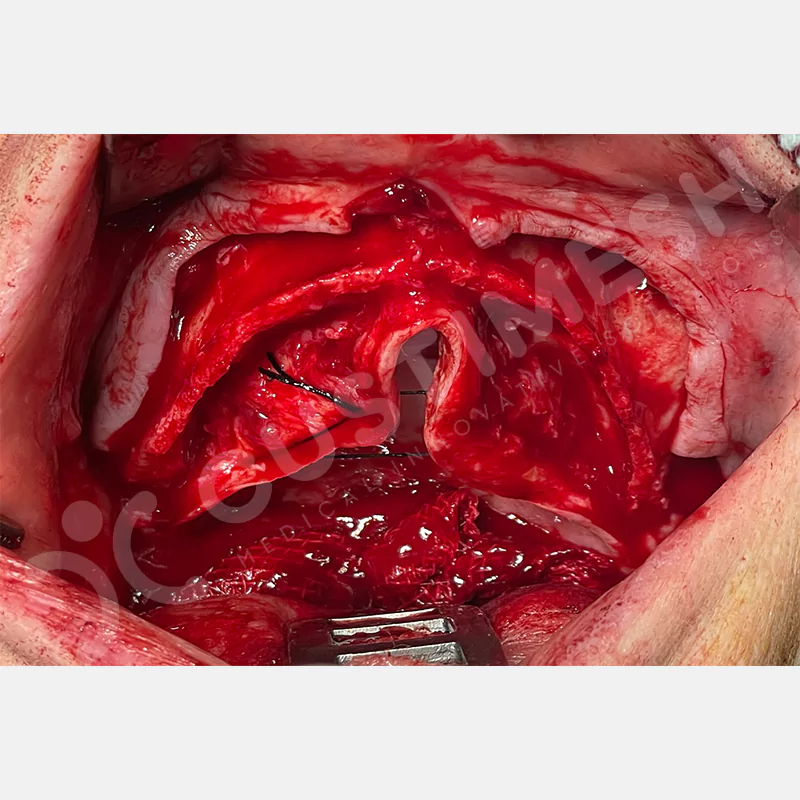

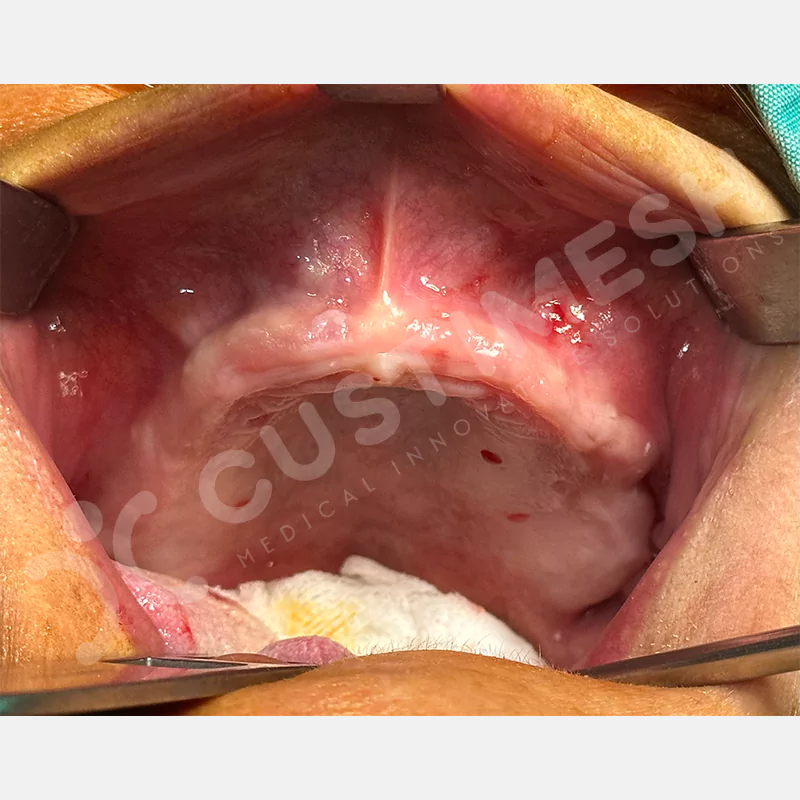

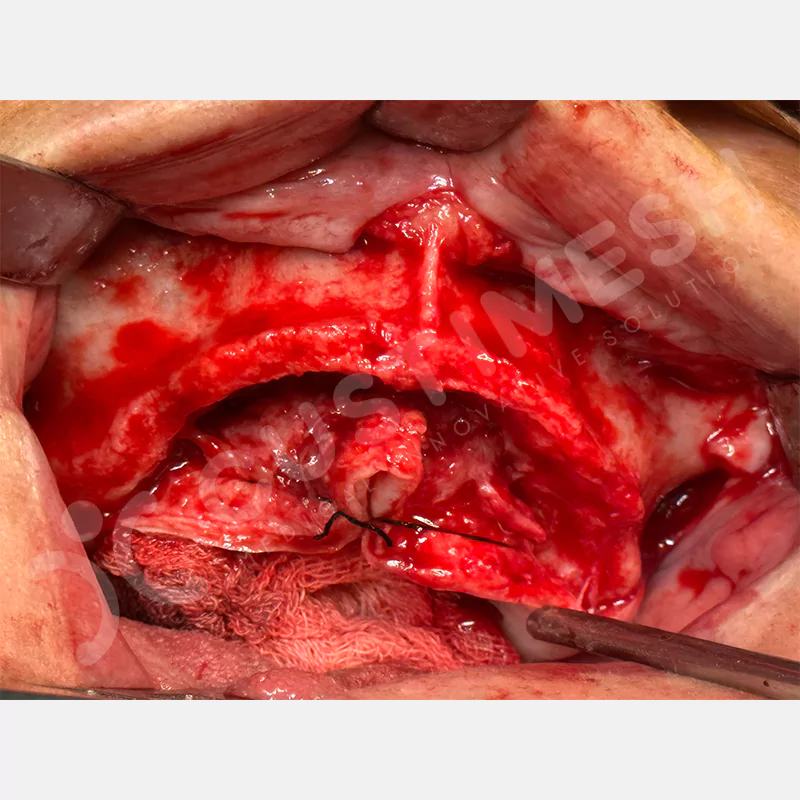

CASE 1

CASE 2

CASE 3

CASE 4

65+

40+

35+

Organisations we work with

Yıldırım Beyazıt Mah. Aşık Veysel Bulvarı No:63/T Erciyes Teknopark Melikgazi/Kayser Türkiye

Monday-Saturday 9:00 – 18:00